Laminated Magnets-Arc

Description

Reviews

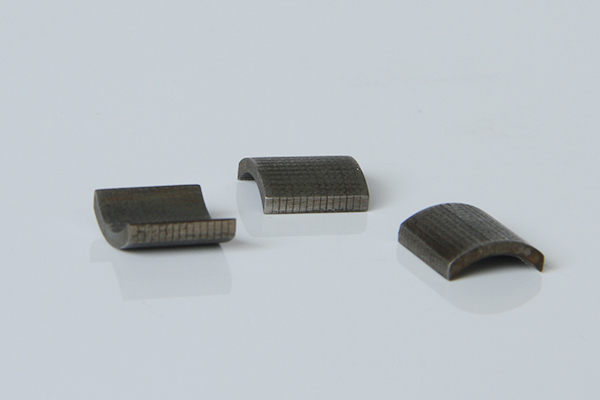

Laminated Magnets-Arc

In the permanent magnet synchronous motor, since the rotor rotates in synchronization with the stator, we offen ignore the eddy current loss in the rotor. In fact, stator slot effect, non-sinusoidal distribution of winding magnetic force and the harmonic magnetic potential generated by the harmonic currents in the coil winding will also cause eddy current loss in the permanent magnets of the rotor, the rotor yoke, and the metal sheath of the bundled permanent magnets.

Since the highest working temperature of sintered NdFeB magnets is 220℃(N35AH), the higher working temperature, the lower magnetic properties of NdFeB magnets, the conversion and power of motor will be reduced. This is called heat loss! These eddy current loss may cause high temperature rises, causing local demagnetization of the permanent magnets, which is particularly serious in some high-speed or high-frequency permanent magnet sychronous motors.

Demagnetization curve of sintered magnet (N35AH) at different temperature

The heat loss mainly comes from the electromagnetic eddy current in the operation of the motor. Thus, multiple stacking method( it needs insulation between each magnets) to reduce this heat loss.

Scope of application: High-speed permanent magnet motor.

Advantage: It can reduce the energy loss caused by electromagnetic eddy currents.

From this research and development project to test samples, our technical team spent more than a year on this project. We always believe that technological R&D is the core competitiveness of a company. As long as customers put forward ideas, we can provide one-stop solution service.

Scope of application: High-speed permanent magnet motor.

Advantage: It can reduce the energy loss caused by electromagnetic eddy currents.

From this research and development project to test samples, our technical team spent more than a year on this project. We always believe that technological R&D is the core competitiveness of a company. As long as customers put forward ideas, we can provide one-stop solution service.